As a component capable of 360-degree rotation and signal transmission, slip rings are widely used in various industrial electromechanical equipment and high-end consumer electronic products representing advanced human technology. In the aerospace field, there are also many devices that require slip ring support. The most common of these are automated machines and industrial robots in […]

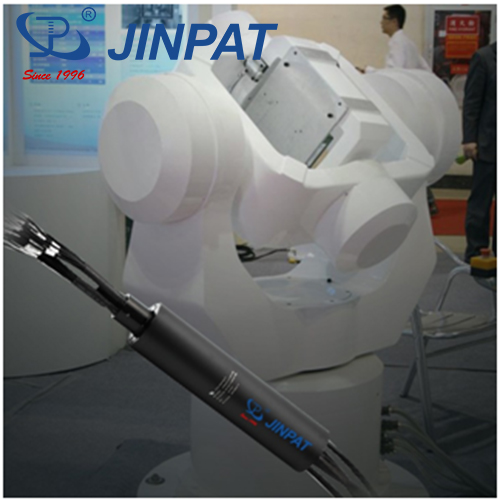

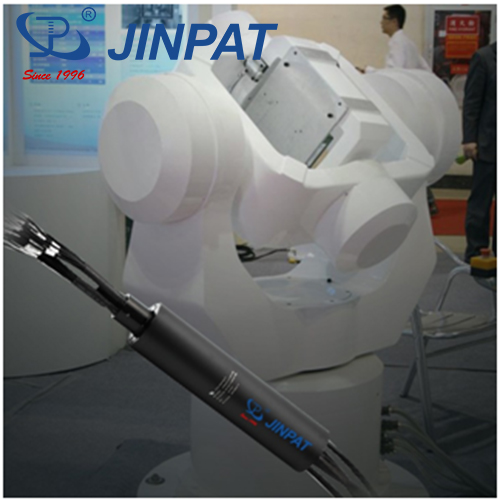

As a component capable of 360-degree rotation and signal transmission, slip rings are widely used in various industrial electromechanical equipment and high-end consumer electronic products representing advanced human technology. In the aerospace field, there are also many devices that require slip ring support. The most common of these are automated machines and industrial robots in the manufacturing process of various aircraft components, as well as in some aerospace engine testing and product operation simulation equipment.

In addition to the large amount of high-precision and advanced equipment, there is another crucial factor in the aerospace industry: pilots and astronauts. To ensure their physical health, aerospace engineers have invented a variety of medical simulation equipment, many of which also incorporate contact rings. As a world-renowned slip ring manufacturer, JINPAThas developed many enclosures for electro-mechanical equipment in the aerospace industry, and is also able to supply specialized slip rings for medical simulation equipment in this field.

Take, for example, a manned rotary platform used for aviation medical training. Its design is similar to that of many three-axis test platforms, except that it must support the weight of the pilot, so its volume is much greater than that of a three-axis platform used to test some electromechanical equipment. With respect to the use of slip rings, the product used in this way, the three-axis platform, is relatively simpler than that used in test platforms. This platform only needs to transmit trainee health information such as heartbeat and electrocardiogram, and no more than one group of switching signals is added so that the pilot can stop the platform in case of an emergency during pilot training.

JINPAT has developed many specialized slip rings for this type of multi-axis platform, including a unique technology that JINPAT pioneered among industrial manufacturers: the use of multiple slip rings integrated with Ethernet in series, which can ensure extremely low signal loss even after multiple Ethernet integrations. While the functions integrated into a manned rotary platform used for aviation medicine training are relatively simple, it is also practical to use slip rings integrated with Ethernet signals to transmit signals generated by the payload axis system, since the monitoring terminals for this type of equipment are modern computers.

keywords integrated slip rings slip ring slip ring optical slip rings optical hybrid slip rings custom slip ring manufacturing slip ring slip ring slip ring

JINPAT photovoltaic slip rings have high quality and competitive price. JINPAT has provided hundreds of models of electro-optical rotary joints for both civil and military industries. Most of JINPAT electro-optical slip rings have high transmission capacity. High-end slip rings can transmit 4K@60FPS high-definition video signals. OVERVIEW Design product sketches and models using SOLIDWORKS 3D Computer […]

With many years of experience in managing various types of projects, the management team of JINPAT is able to eliminate all obstacles that arise during the execution of projects to ensure that the technology is followed and the products are manufactured successfully. In addition, JINPAT understands the importance of good documentation. Documents such as certificates […]

JINPAT carries out precision machining of all components of its products. At all stages of production, from drawing to molding, JINPAT is committed to being precise and ensuring that the best slip rings are produced. With the ability to machine parts to a tolerance of 5 microns, our experienced, highly skilled team uses the latest […]

JINPAT welding technicians are experts in Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Gas Tungsten Arc Welding (GTAW) and Semi Metal Arc Welding (SMAW). They are dedicated individuals who value precision and aesthetics in the production of machine components. OVERVIEW Welding procedures comply with codes such as ASMEIX, AWS, DIN, API, B31.1, […]

JINPATElectronics is a customer-oriented corporation. We do our utmost to provide our customers with high-standard solutions for transmission including rotation. Up to now, JINPAT has provided its services to more than 10,000 customers worldwide. Each slip ring produced by JINPAT undergoes a series of rigorous and systematic inspections and durability tests before being delivered to […]

With advanced testing and measuring devices, JINPAT’s Quality Control Department conducts systematic inspections of our products. Our quality measurement system complies with ISO 9001:2015. JINPAT has great confidence in its products and has earned a good reputation for producing products of unrivaled quality. REVIEW Detailed inspection and provision of data in the form of documentation […]